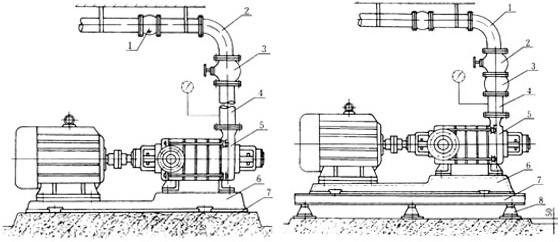

I:The multi-stage pump must be carefully installed. The below introduced of vertical pump installation method:

1、Vertical multi-stage centrifugal pump inlet pipe bend a lot.

If there are many bent tubes on the pump inlet line,It will increase water resistance. And the bend should be vertical,Levels are not allowed,Avoid air accumulation.

2、When installing incoming water pipe, horizontal or upward.

This approach is wrong.

The pump inlet pipe should be tilted to the pump,Not supposed to be horizontal,It shouldn’t go up.

3、The multi-stage pump inlet cannot be connected directly with the bend pipe.

4、Multi-stage centrifugal pump outlet pipe outlet above normal water level

5、It is best if you can install the check valve.

II:The following points need to be noted when installing a multi-stage centrifugal pump:

1,when the motor and pump combination installation, should spread the pump shaft coupling,and retain 3-5 mm gap, in this way, can ensure that the space between two pump and motor couplings.

Note: to determine the floor is flat, grouting should be equipment level adjustment later.

Caution: to make a successful installation, coupling adjustment must be correct, flexible coupling can’t compensate for any obvious disorders.Dissonance may cause rapid wear, noise, vibration and damage to equipment.Therefore, the coupling must be adjusted within the given limits.

Caution: must take measures to support the pump inlet and pump outlet pipe, prevent the pump inlet and pump discharge load is too big.

2,the pump and motor shaft centerline should be on the same horizontal line.

3,and pump can only carry their own strength, unable to bear any foreign power.